Our Transformation Technology Inspection service represents a pioneering approach to evaluating and optimizing technological infrastructure.

Leveraging cutting-edge methodologies and advanced analytics, we delve deep into your systems, uncovering opportunities for enhancement and innovation.

From cybersecurity audits to performance assessments, our inspections are comprehensive, ensuring your technology aligns with your organizational goals and industry standards.

With our transformative insights, we empower businesses to evolve, adapt, and thrive in an ever-changing digital landscape.

OVERVIEW

Our Transformation Technology Inspection service is at the forefront of innovation, offering comprehensive assessments of technological infrastructure to drive organizational evolution and excellence.

Leveraging advanced methodologies and cutting-edge analytics, we delve deep into your systems, uncovering inefficiencies, vulnerabilities, and opportunities for enhancement.

Our inspections cover a wide range of areas, including cybersecurity audits, performance evaluations, and compliance assessments, ensuring alignment with industry standards and best practices.

THE GOAL

WHY USE DIGITAL TECHNOLOGIES?

DIGITAL ROADMAP

TYPICAL DIGITAL WORKFLOW

01 Fieldwork

02 Data Processing

03 Modelling

04 Digital Asset Management

05 Mixed Reality

Todays Connected Work Environments

KEY AREA FOCUS

Safety Improvement within brown field terminals

Artificial Intelligence

Use existing CCTV assets to detect non-conformance and provide real time safety alerts.

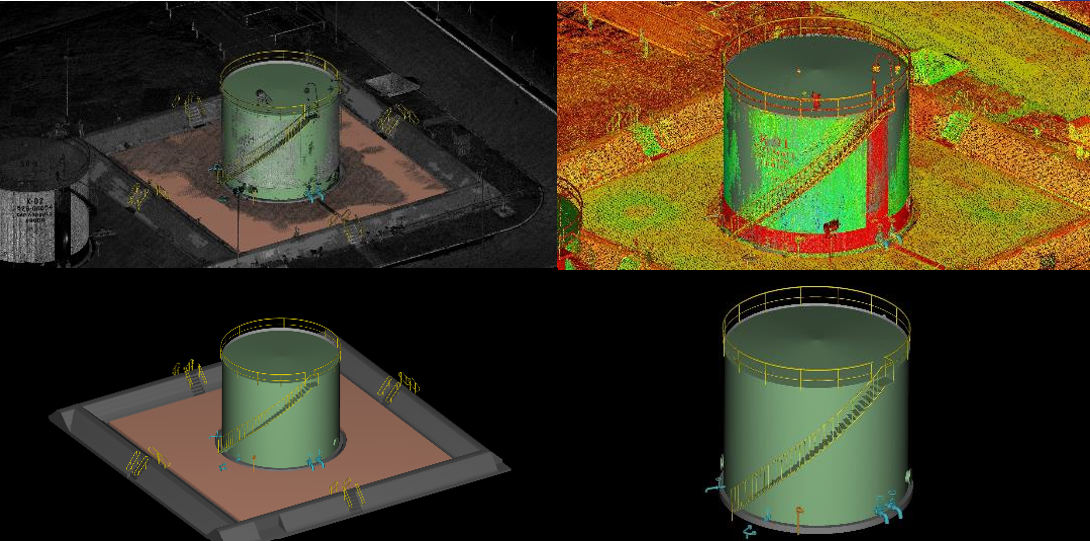

3D Digital Environments

Safely assess and manage operational environments.

Process and Efficiency Improvement

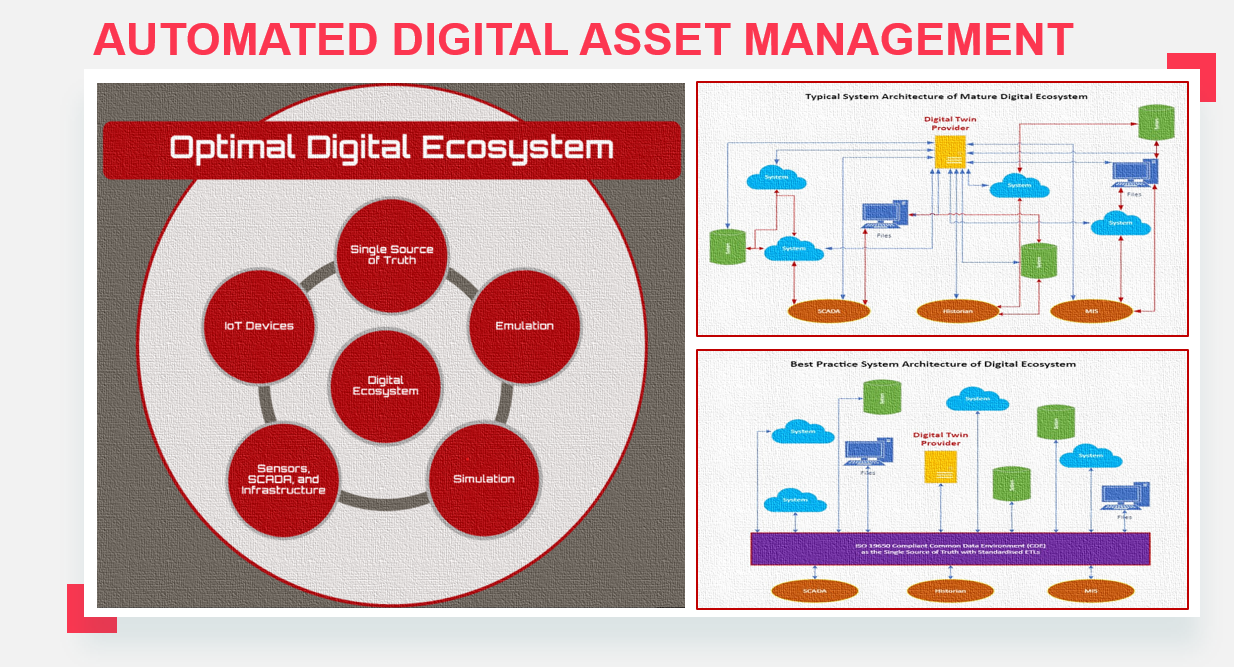

Automated Digital Asset Management

Automation of operational complexity reduces rework and human error.

Simulation Modelling

Predict probable future states of value chains, given near-term constraints.

Drone Inspections

Decreases time and cost which in turn increases operational utilisation and availability.

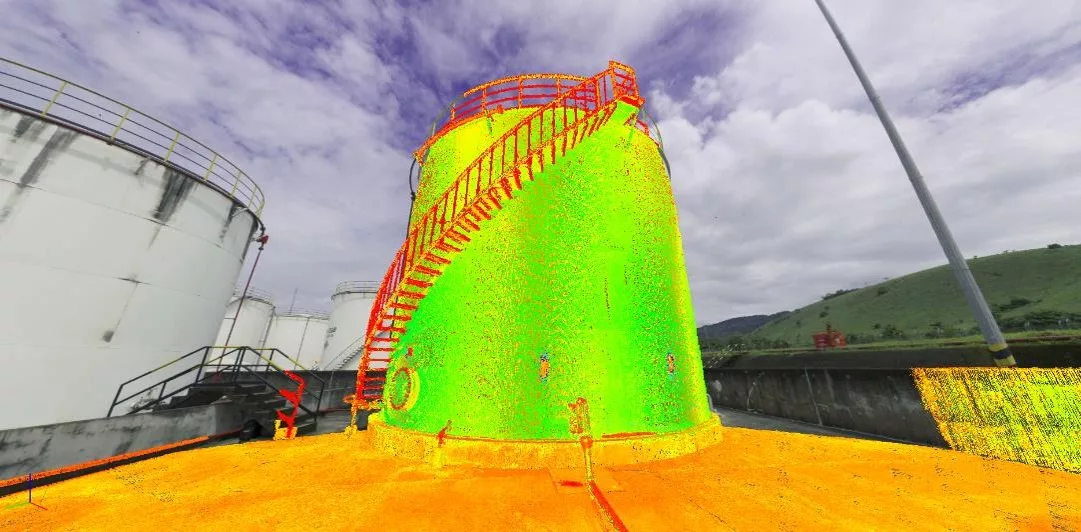

Digital Tank Inspections

Proactive condition monitoring with risk-based inspections prolong in service intervals of tank assets

Simulation Modelling – Process Optimization

- Predict probable future states of value chains, given near-term constraints.

- Strategy and “What-if” scenario modelling with automated cost and production optimization

Application

- Process Optimization

- Resource and Asset Allocation

- Efficiency gains

Short Interval Control - Integrated Decision Making

- Activity Based Costing and Cost Optimization

Accuracy

- Increase accuracy of near-term planning forecasting

- Understand true impact of variation

- Reduce Human error through integrated decision making

Versatility

- Make mistakes in the model prior to operational implementation.

- Understand the impact of decisions and strategy across the entire value chain

- Make the optimal decisions in real time in a dynamic operational environments.

Financial impact

- Better understand the impact of operational strategy on cost.

- Optimize WIP and nonvalue added processes.

- Optimize resource and asset allocation.

- Enable Activity Based Costing

Reliability

- Self validating feedback loops ensure accurate data as inputs, thereby ensuring consistent and reliable results aligned with expectations

- Visualize and validate all data in ERP, MES, and other systems

Impact on HSE

- Simulate unplanned safety events for understanding effectiveness of safety procedures and the true impact on operations

- Understand risk in the true financial impact of safety breaches