PSAIM Audit

To achieve “Zero Major Accident” and “Safe & Reliable Operation”

PSAIM AUDIT ELEMENTS

The basic principles of PSAIMS are underpinned by a commitment to Process Safety & Integrity Assets (Process Safety & Asset Integrity-PSAI), which are run dynamically and sustainable through the implementation of 4 (four) pillars and 15 (fifteen) elements of PSAIMS to achieve “Zero Major Accident” and “Safe & Reliable Operation”

PSAIM SOLUTION

PSAIM MILESTONE

Conduct PSAIM Audit

- Conduct PSAIM Training

- Development of PSAIM procedures and guidelines

- Sustain PSAIM implementation

PERFOMANCE CRITERIA

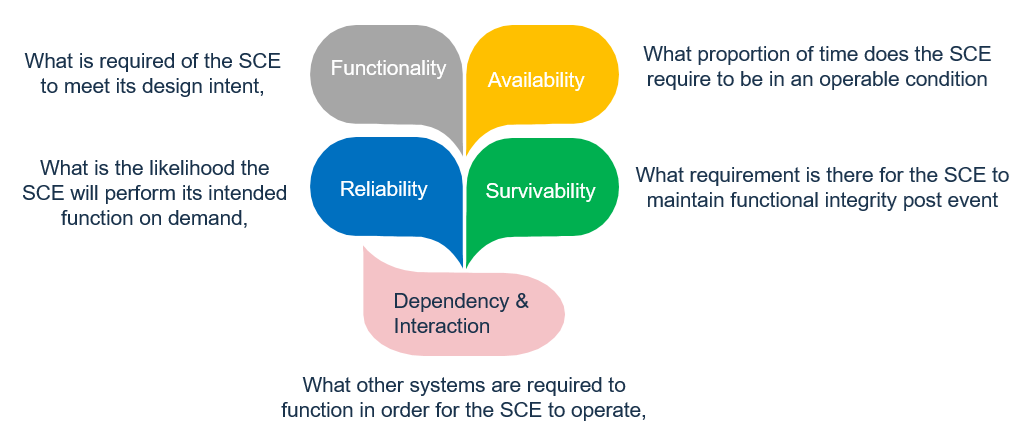

Performance Standard consists of performance criteria specific to each lifecycle stage on which the SCE is assessed and verified. The criteria are generally defined in terms of:

TRAINING PSAIM

Through the audit finding BN BV will conduct the need of PSAIM training matrix to develop a level of understanding of how the safety is assured through the Safety Case, and the reliable performance of critical asset in accordance with Performance Standards in performing key functions to minimize the consequences of realized MAHs in Pertamina holding.

Training is practical instruction in job and task requirements and methods. Performance assurance is the means by which workers demonstrate that they have understood the training and can apply it in practical situations

SAFETY CASE

CONTROLING OPERATIONAL RISKS

PSAIM AUDIT

The PSAIM AUDIT will be proposed identify company’s PSAIM management system program, identify its strengths and weaknesses, unfulfilled requirements, and highlight areas that need improvements

In order to have a full commitment from the top management for reducing the risk of major incidents.

Asset Integrity Policy, Strategy and Leadership

The policy documents should be signed by the Top Level management to demonstrate that such commitments are truly become company’s directive.

Asset Integrity Management System

Organization at the corporate general documents / procedure of policy, strategy, objectives, plans, activities, processes and organizational structures.

Process Safety Management Program

The PSM program integrates management practices, procedures and technologies intended to prevent or minimize the consequences of catastrophic incidents related to the release of toxic, reactive, flammable or explosive chemicals

Check list of 14 Element PSM will be perform for interview

Review and Continuous Improvement

It includes elements such as incident investigation, performance metrics, periodical audit / verification, KPI, management review, and continuous improvement.

Integrity, Reliability & Process Safety Assessment

It includes of Integrity, reliability and technical safety assessment to ensure people, systems, processes, resources are fit for purpose to prevent process related incidents and injuries over the whole lifecycle of the assets.

Performance Assurance

Physical asset performance assurance is composed of the basic activities at the ground floor level that maintain the design intent through life: Maintenance, inspection and testing.

CMIMS and Reporting

All activities of means of assurance should be monitored and fully recorded to Computerized Maintenance & Inspection Management System (CMIMS) Process Safety Management Program.

System integration

AIM software should integrated into one system dashboard, it will be beneficial on system and process alignment, reducing cost in maintaining, minimizing trouble, and increasing efficiency and effectiveness.

Competence

Competence of the people involved at any stage or activity of the physical asset integrity management is fundamental Integrity, Reliability & Process Safety Assessment

Competence of people includes education, training and experience.